Since founded in 1967, TOKEN has been satisfying customer needs with various kinds of coil processing machines. All machines are designed, assembled and checked prior to shipment in our factory. We are proud of "Made in Japan".

-

1Cut to length lines

Cut to length lines

Actual record

- Thickness : 0.1 mm - 25.4 mm

- Width : up to 2,300mm

-

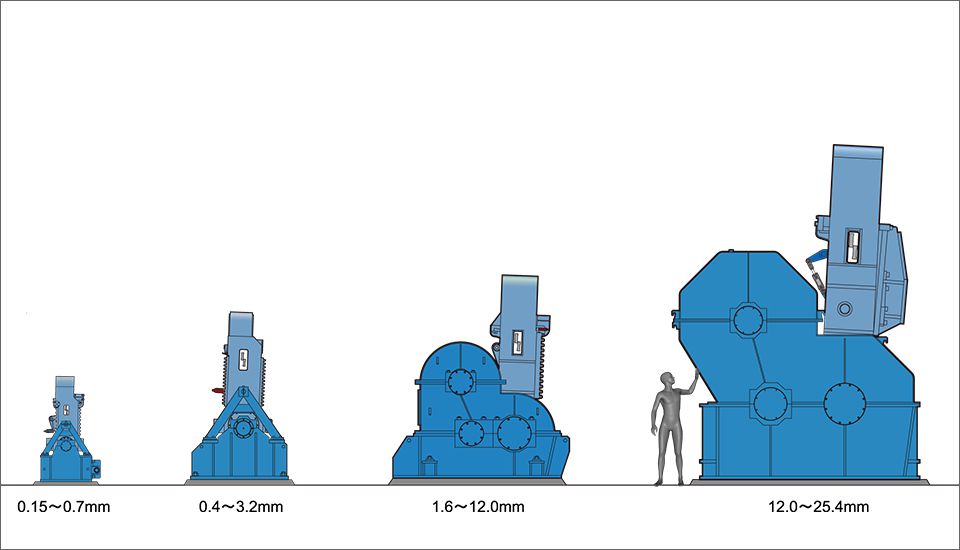

2Levellers

Levellers

TOKEN developed "The next generation levellers" in which inner residual stress is minimized. The results are most suitable sheets for laser cut process. TOKEN has methods to eliminate so called "the torque circulation phenomenon in roller levellers" which causes polygonal wear of rolls, breakage of universal joints and gear train.

-

3Flying shears

Flying shears

TOKEN utilizes roller type bearings and slides for all moving parts to eliminate any bushes and sliding liners. Therefore low maintenance cost, low vibration and low noise are achieved. Additional advantages are the clamping mechanism and the numerically controlled gap of the blades.

-

4Automatic pilers

Automatic pilers

TOKEN design team has solutions for any stacking application from stacking sheets with very delicate surface to landing heavy gauge plates with large inertia. TOKEN will recommend the best layout to suite your needs.

-

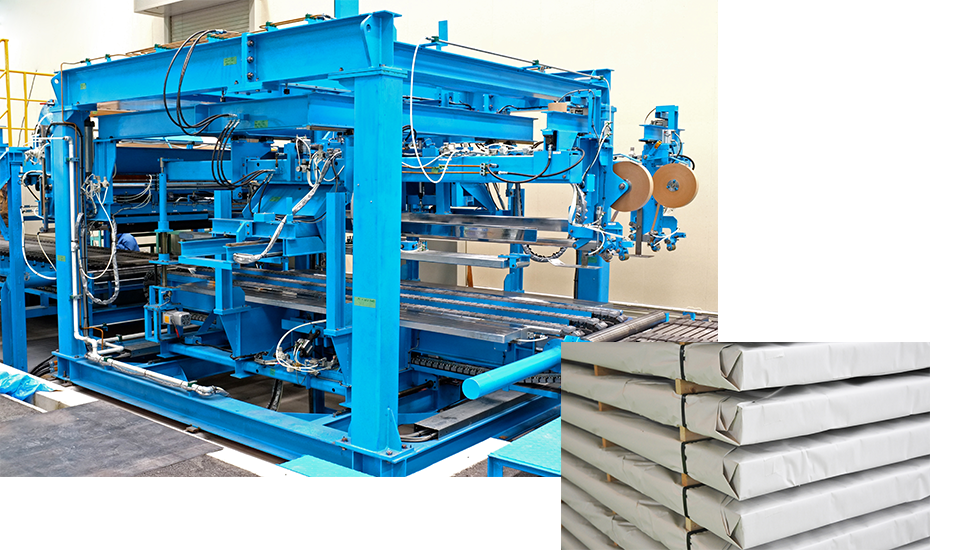

5Automatic packing process

Automatic packing process

TOKEN has the solutions for all packaging requirements. Some experience include automation of paper wrapping, taping the paper wrap, applying corner angles, binding with metal band, inserting wooden pallet and stacking.

-

6Slitter lines

Slitter lines

Actual records- Thickness : 0.1 mm – 16.0 mm

- Width : up to 1,900 mm

-

7HES slitters

HES slitters

HES does not require the use of spacers. The uniquely designed arbor grips blades by hydraulic force. More than 80 units were sold in Japan.

-

8SVAC

"Slitter with Vertical Arbor Changer"SVAC "Slitter with Vertical Arbor Changer"

This high-tech robot system assembles the tooling for the slitter without any labor.

-

9Cold plate levellers

Cold plate levellers

This high rigidity leveller was manufactured to rescue rejected plates from the rolling mill.